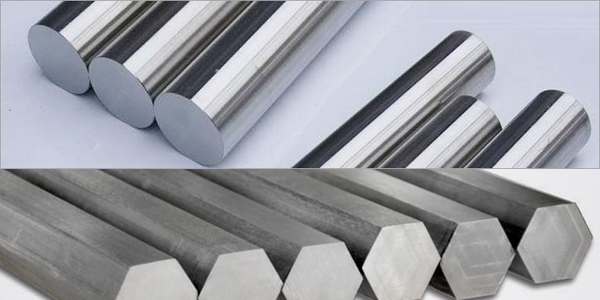

Titanium is fairly hard (although not as hard as some grades of heat-treated steel), non-magnetic and a poor conductor of heat and electricity. Machining requires precautions, as the material will soften and gall if sharp tools and proper cooling methods are not used. Like those made from steel, titanium structures have a fatigue limit which guarantees longevity in some applications.

Titanium alloys have lower specific stiffnesses than in many other structural materials such as aluminium alloys and carbon fiber.

|

CHEMICAL, PHYSICAL AND MECHANICAL PROPERTIES |

|||||||

|

CHEMICAL COMPOSITION |

ASTM Grade |

||||||

|

(Max. Values) |

1 |

2 |

5 |

7 |

9 |

12 |

23 |

|

N, Nitrogen |

0,03 |

0,03 |

0,05 |

0,03 |

0,02 |

0,03 |

0,03 |

|

C, Carbon |

0,1 |

0,1 |

0,1 |

0,1 |

0,05 |

0,08 |

0,08 |

|

H, Hydrogen |

0,015 |

0,015 |

0,0125 |

0,015 |

0,013 |

0,015 |

0,0125 |

|

Fe, Iron |

0,2 |

0,3 |

0,4 |

0,3 |

0,25 |

0,3 |

0,25 |

|

O, Oxygen |

0,18 |

0,25 |

0,20 |

0,25 |

0,12 |

0,25 |

0.13 |

|

Pd, Palladium |

0,12-0,25 |

||||||

|

Al, Aluminum |

5,5-6,75 |

2,5-3,5 |

5,5-6.5 |

||||

|

Mo, Molybdenum |

0,2-0,4 |

||||||

|

V, Vanadium |

3,5-4,5 |

2,0-3,0 |

3,5-4,5 |

||||

|

Ni, Nickel |

0,6-0,9 |

||||||

|

Ti, Titanium |

Bal. |

Bal. |

Bal. |

Bal. |

Bal. |

Bal. |

Bal. |

| MECHANICAL PROPERTIES | |||||||

|

Tensile strength, min (Mpa) |

240,00 |

345,00 |

895,00 |

345,00 |

620,00 |

483,00 |

828,00 |

|

Yield strength, 0,2% Offset, min (Mpa) |

170,00 |

275,00 |

825,00 |

275,00 |

483,00 |

345,00 |

759,00 |

|

Elongation (in 4D, min, %) |

24,00 |

20,00 |

10,00 |

20,00 |

15,00 |

18,00 |

10,00 |

|

Reduction of Area, min, % |

30,00 |

30,00 |

25,00 |

30,00 |

25,00 |

25,00 |

15,00 |

|

Hardness * Interpolated |

Rb70 |

Rb80 |

Rc36 |

Rb80 |

Rc28 |

Rc17* |

|